Conveying Plastic Pellets

The Problem

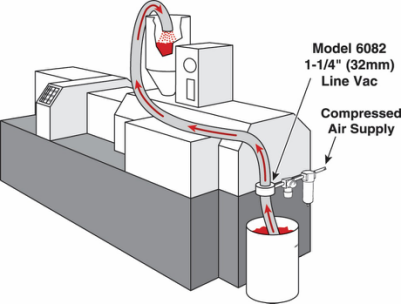

Injection moulding machines transform plastic pellets into various plastic products. The pellets are gravity fed from a hopper on top of the machine. The “bucket and ladder” method of replenishing the hopper was inefficient and expensive.

The Solution

A Model 6982 1-1/4” (32mm) Line Vac Kit was used to convey the pellets up to the hopper. The mounting bracket included with the kit was used to secure the Line Vac to the machine. A filter assured no contamination of the plastic material and a regulator controlled the plastic flow rate.

Comment

Unlike mechanical transfer systems that break down or wear out, the Line Vac has no moving parts. This low-cost method of conveying also gives precise control of material flow into the hopper.

Copyright 2019 © Compressed Air Australia | Website Design Web365 Darwin