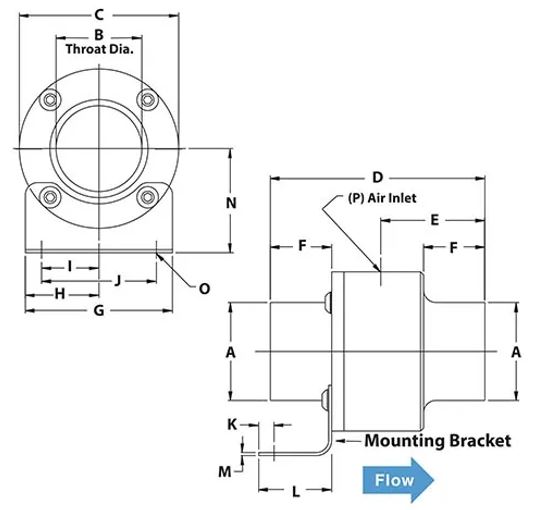

| Ultra Duty Line Vac Models |

Hose Size | ||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| A | B | C | D | E | F | G | H | I | J | K | L | M | N | O | P | ||

| 170125 | in | 1.25 | 1 | 2.38 | 5.56 | 3.53 | 1 | 2.5 | 1.25 | 1 | 2 | 0.31 | 1.61 | 0.06 | 1.68 | 0.28 | 1/4 FNPT |

| mm | 32 | 25 | 61 | 141 | 90 | 25 | 64 | 32 | 25 | 51 | 8 | 41 | 2 | 43 | 7 | ||

| 170150 | in | 1.5 | 1.25 | 2.75 | 5.81 | 3.56 | 1.25 | 2.5 | 1.25 | 0.86 | 1.73 | 0.25 | 1.44 | 0.06 | 1.88 | 0.28 | 3/8 FNPT |

| mm | 38 | 32 | 70 | 148 | 90 | 32 | 64 | 32 | 22 | 44 | 6 | 37 | 2 | 48 | 7 | ||

| 170200 | in | 2 | 1.75 | 3.25 | 5.81 | 3.56 | 1.25 | 3 | 1.5 | 1.17 | 2.34 | 0.28 | 1.48 | 0.06 | 2.13 | 0.28 | 3/8 FNPT |

| mm | 51 | 45 | 83 | 148 | 90 | 32 | 76 | 38 | 30 | 59 | 7 | 38 | 2 | 54 | 7 | ||

Ultra Duty Line Vac™

Optimised for abrasive materials, this powerful, wear-resistant conveyor moves material over extended distances.

What Is The Ultra Duty Line Vac?

EXAIR’s Ultra Duty Line Vac™ is a powerful, wear-resistant conveyor designed for moving abrasive or heavy materials like sand, blasting media, and powders. Built from hardened alloy, it handles long-distance conveying in both vertical and horizontal applications. Available in sizes from 1-1/4″ (32mm) through 2″ (51mm), the Ultra Duty Line Vac™ offers high throughput performance and a compact, maintenance-free design with no moving parts. Kits also available.

How The Ultra Duty Line Vac Works

Compressed air flows through the inlet (1) into an annular plenum chamber (2). It is then injected into the throat through directed nozzles (3). These jets of air create a vacuum at the intake (4) which draws material in and accelerates it through the unit (5) for conveying over long vertical or horizontal distances.

Warning : Do not use EXAIR Line Vacs with any material that can become an explosive mixture.

Watch the Video

Line Vac Drum Cover

EXAIR’s fine mesh non-woven Drum Cover is built to fit over the top of 205 or 60 litre drums. The breathable material allows the air from a Line Vac air operated conveyor to circulate, whether moving material in or out of the drum. The cover prevents contamination of your material and keeps material from escaping the drum, which keeps your work environment cleaner and safer.

Since it is fabricated to fit 205 or 60 litre drums, it is the simplest of solutions when needing a containment vessel for your transferred scrap, trim, waste, parts, chips or pellets.

It is suitable for Line Vac conveyance hoses from ¾” (19mm) through 3.4” (86.4mm) outside diameters and comes complete with hose clamps and a durable spring buckle strap for quick and easy installation.

Performance

| Size | Air Consumption | Vacuum | ||||

| 80 PSIG | 5.5 BAR | |||||

| Model | in | mm | SCFM | SLPM | H2O | kPa |

| 170125 | 1.25 | 32 | 49 | 1,388 | -83 | -21 |

| 170150 | 1.5 | 38 | 55 | 1,557 | -60 | -15 |

| 170200 | 2 | 51 | 75 | 2,124 | -42 | -10 |

Applications

- Hopper loading

- Fibre tensioning

- Material conveying

- Waste/trim removal

- Chip removal

- Part transfer

- Filling operations

Advantages

- Hardened alloy construction that has been optimized for abrasive materials

- Wear-resistant

- Highest throughput capability

- Compact

- Quiet

- No moving parts

- Fits standard hose, tube and pipe

Ultra Duty Line Vacs are available individually and in kits for use with NPT threaded pipe. Ultra Duty Line Vac Kits include an Ultra Duty Line Vac, filter separator and pressure regulator (with coupler).

Ultra Duty Line Vac Dimensions

Models

| Ultra Duty Line Vac Models | ||

| Ultra Duty Line Vac Only | ||

| Ultra Duty Line Vac Kits | includes an Ultra Duty Line Vac, mounting bracket, filter separator and pressure regulator (with coupler) | |

| Inlet / Outlet Diameter | Ultra Duty Line Vac Only Model | Ultra Duty Line Vac Kit Model |

| 1-1/4″ (32mm) | BP170125 | BP172125 |

| 1-1/2″ (38mm) | BP170150 | BP172150 |

| 2″ (51mm) | BP170200 | BP172200 |

| Line Vac Drum Cover & Mounting Brackets | ||

| Model | Description | |

| 6850 | Drum Cover Kit includes Drum Cover, strap, 3 stainless hose clamps (¾” – 1¼”, 1½” – 2½” and 3″) |

|

| 6996 | Mounting Bracket For 1-1/4″ (32mm) & 1-1/2″ (38mm) Line Vac Units | |

| 6997 | Mounting Bracket For 2″ (51mm) & 2-1/2″ (64mm) Line Vac Units | |

Accessories

Filters, Regulators, Valves & More

With proper filtration of dirt, moisture and oil from the compressed air supply, EXAIR compressed air products will operate for years with no maintenance required. Use a 5 micron or smaller filter separator on the compressed air supply. To prevent problems associated with oil, use a 0.03 micron or smaller oil removal filter on the compressed air supply. Pressure regulators permit easy selection of the operating pressure, providing infinite control of flow, force and air consumption.

Learn More

Previous

Previous